TIMBER FRAMED WALLS

Thanks to state-of-the-art wood processing and assembly technologies, prefabricated timber structures are becoming a real alternative to most technologies used in construction today.

The cost of the building, which is known at the start of the project, remains unchanged throughout its completion.

Precision and quality achieved through prefabrication – modern machines and qualified employees.

The ability to maintain continuity of the assembly process without the downtime due to technological and weather issues or due to lack of construction team.

Lower construction costs in terms of contracting and coordinating several construction teams and the supply of construction materials.

Larger usable building area – up to 10% – compared to conventional technology.

Thanks to a lower demand for thermal energy, timber structures significantly reduce building maintenance costs.

Healthy microclimate of the building.

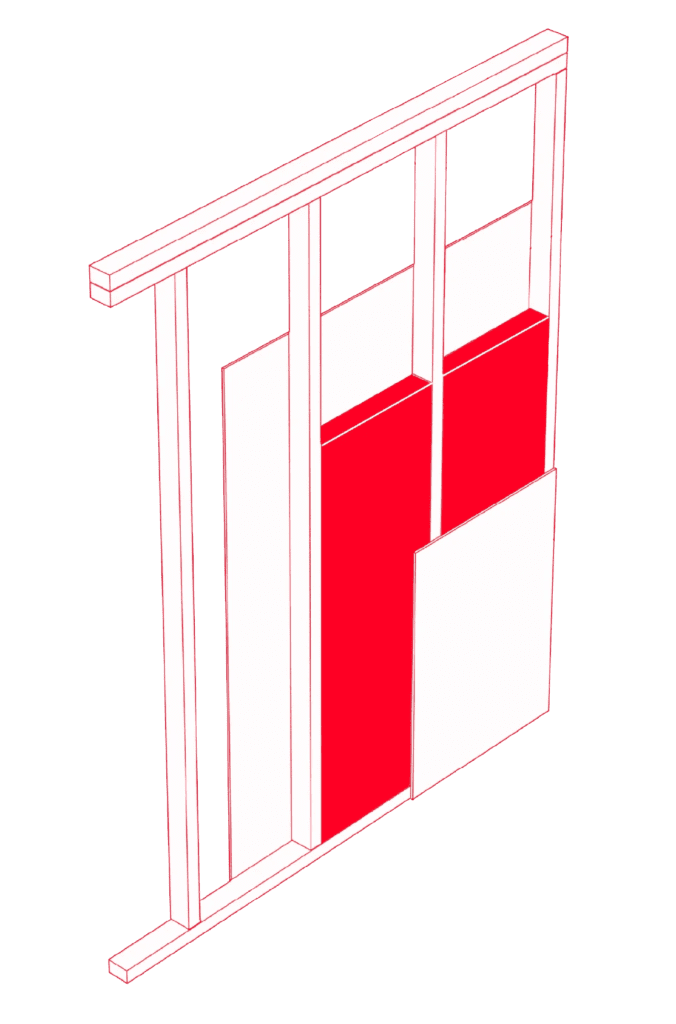

INTERNAL PARTITION WALL

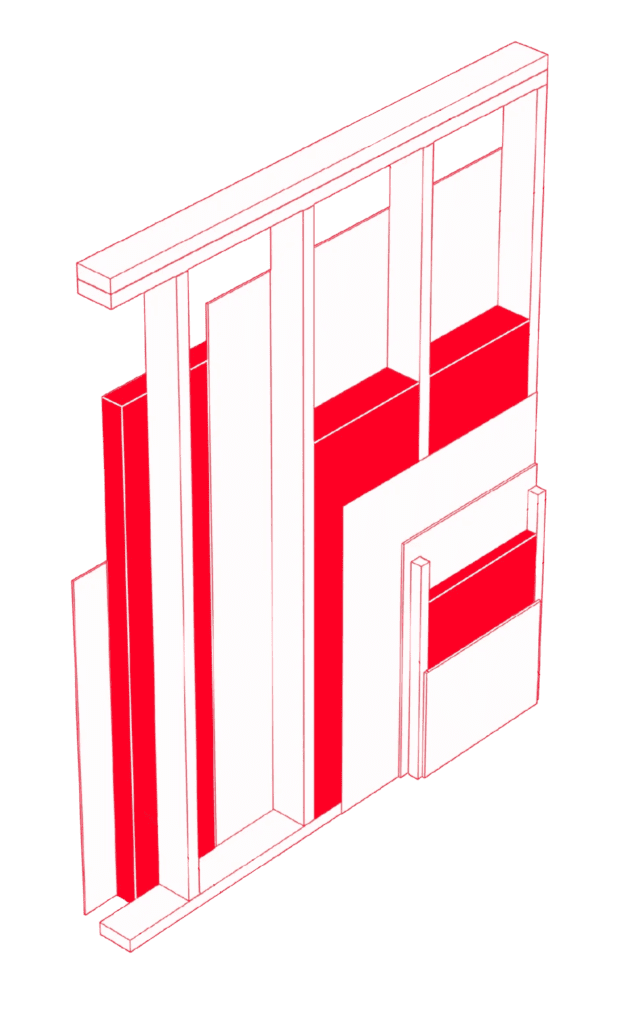

EXTERNAL WALL

WE KNOW A LOT ABOUT THE WOOD AND WOODWORKING

Top quality materials

The prefabricated timber framed walls we offer are produced from the highest quality materials, so the final product meets safety standards and guarantees optimal performance characteristics.

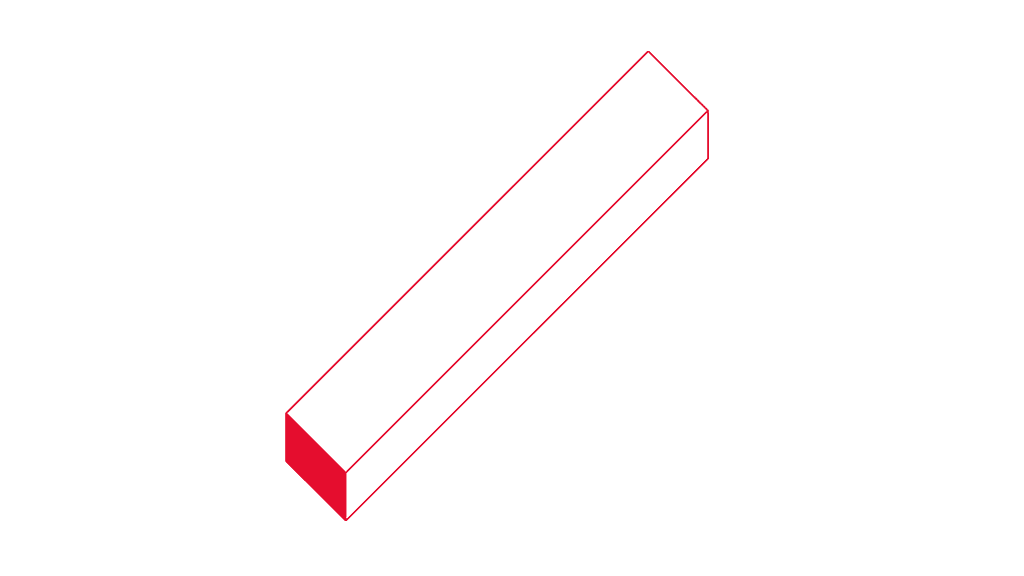

Structural timber C24 , which is the basis of the timber framed wall comes from our sawmill. The material is visually and mechanically strength graded, then dried in computer-controlled kilns to a moisture content of 18% (+/-2%) and planed on four sides with bevelled edges. Proper processing ensures that the wood used is an extremely strong and durable material.

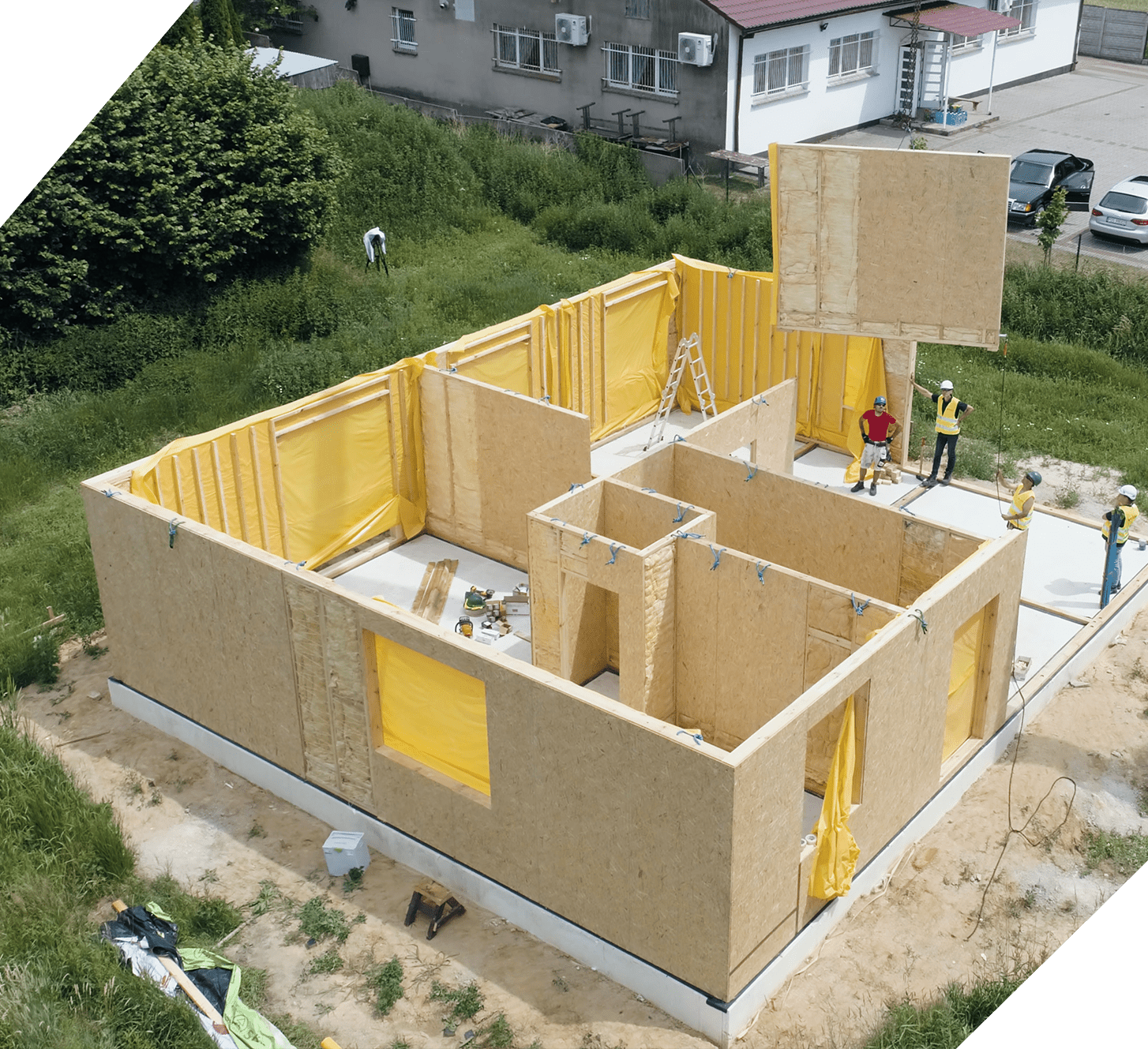

Favorable microclimate for all

We prepare the building elements in the factory on a specially designed assembly table. The basis for implementation is project prepared by our design office. The production of individual building components under proven conditions by an experienced team of workers ensures that the highest level of precision is achieved. This is not possible with masonry houses, which is why timber framed construction has a significant advantage here. It is worth mentioning that thanks to the ability to produce walls in the factory, we can produce our products all year round, regardless of weather conditions.

Prefabricated elements are then transported to the construction site, where they are assembled like blocks into a complete building. The extreme precision of all the elements makes it possible to shorten the time needed to assemble a timber framed building, which is currently a great advantage for investors.

Thanks to the use of wood, which is a natural raw material, prefabricated timber framed houses have a favourable microclimate and therefore have a positive impact on the well-being and health of their inhabitants.

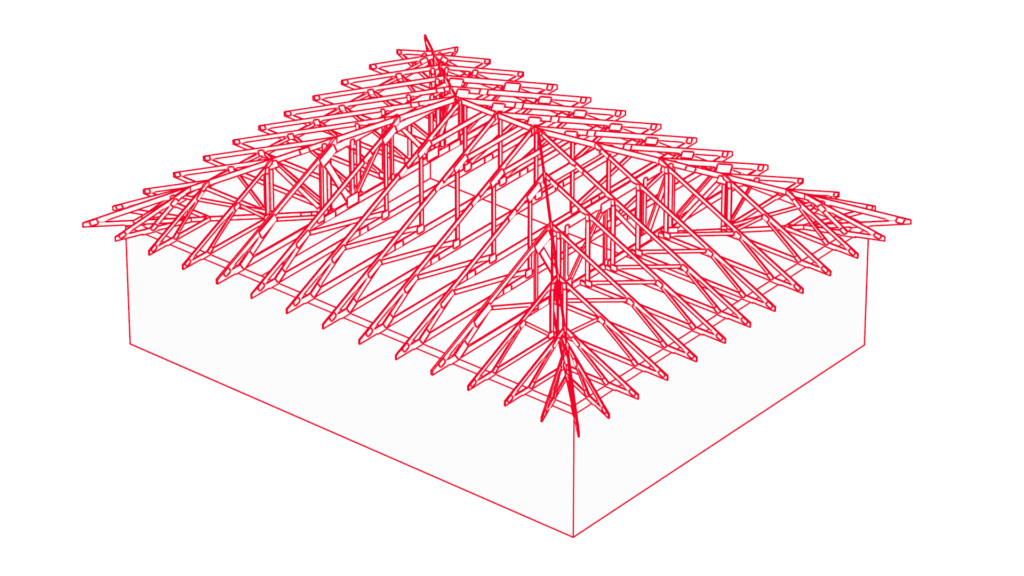

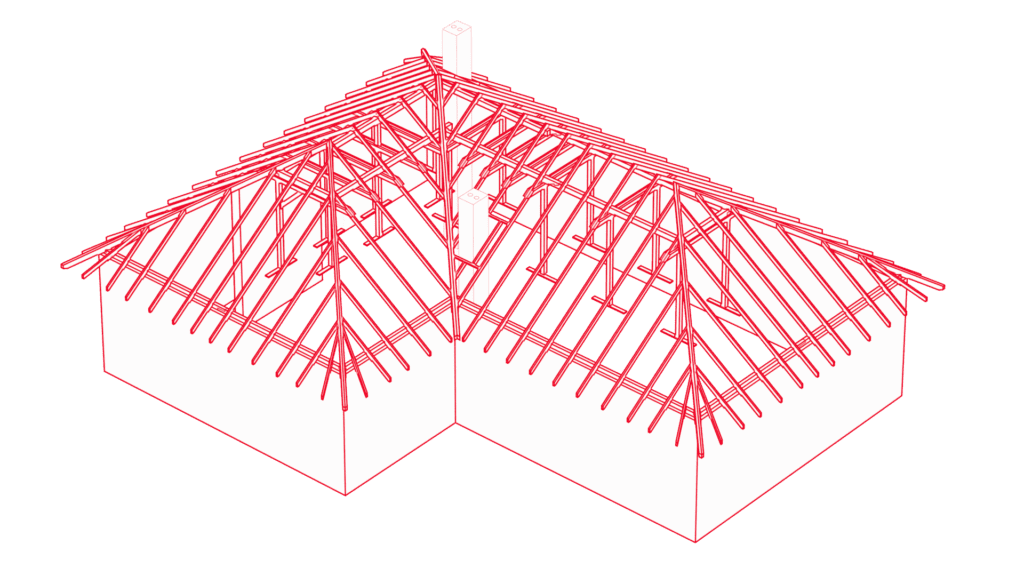

Our offer includes not only external but also internal timber framed walls and roof structures, so that we can provide a comprehensive service for your investment.

From the first step to the last

Further advantages of timber framed houses:

- the material doesn’t need to be seasoned and dried,

- construction time is significantly shorter than in conventional construction,

- less construction waste remains on site, thanks to the delivery of prefabricated components,

- the risk of construction delay is lower, e.g. due to weather conditions,

- frame technology is cleaner and more aesthetically pleasing,

- a large part of the construction process is in one hand – responsibility is not diluted among various contractors.

Product comparison

| NAME | ||||||

| PRODUCT STANDARD | PN-EN 1995 |

|||||

| TYPE OF WOOD | ||||||

| STRENGTH CLASS | ||||||

| MOISTURE | ||||||

| WOODWORKING | ||||||

| PRESERVATIVE TREATMENT (method of protection) | ||||||

| TYPES OF SURFACE QUALITY | ||||||

| BONDING (glue adhesive used for bonding) |