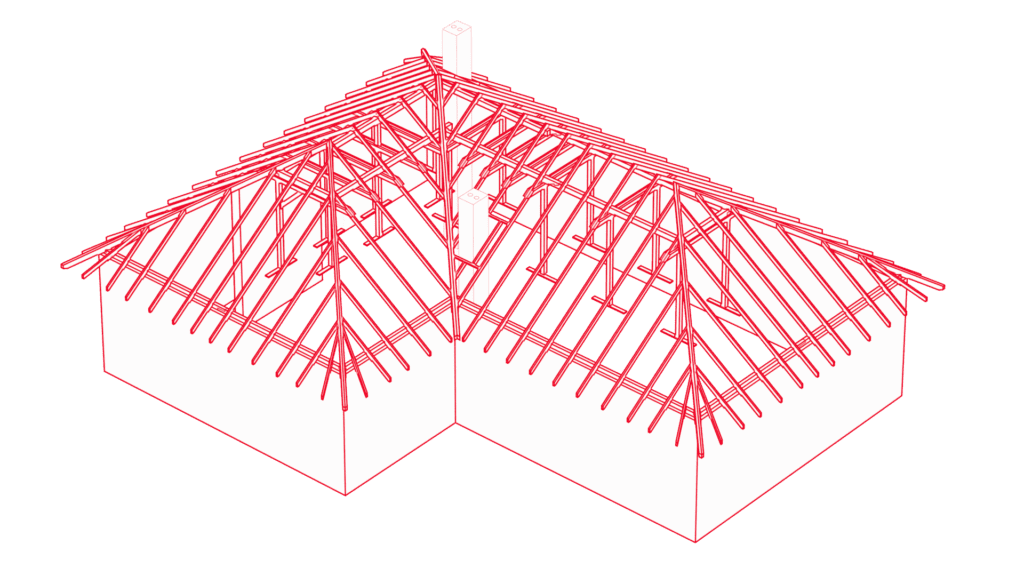

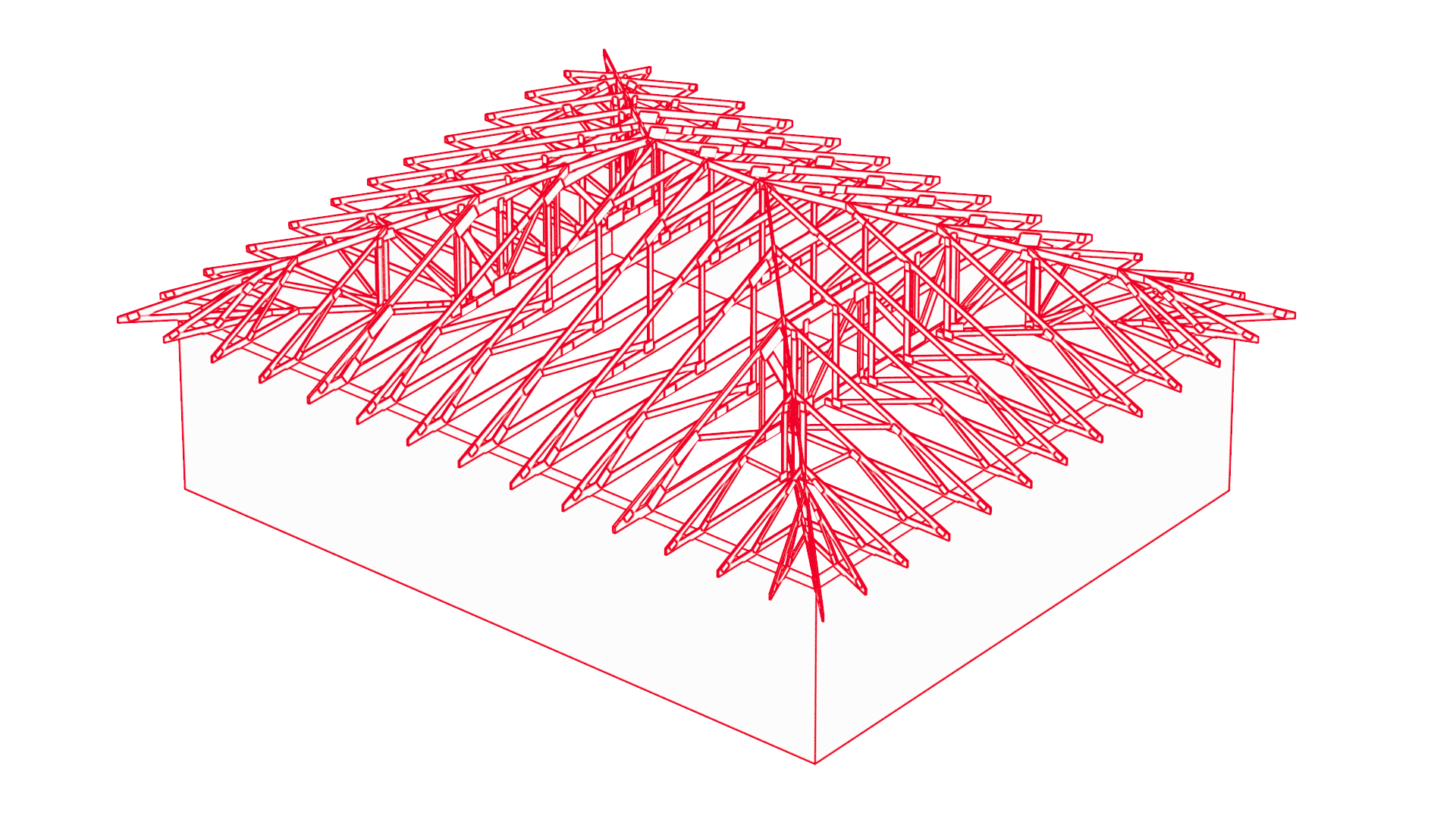

Roof trusses

The prefabricated roof trusses we offer meet the needs of different types of construction:

Single-family residential

Multi-family residential

Industrial construction

Agriculture construction

Commercial construction

Timber framed construction

from the first

to the last step

Support and expert advice

YEARS OF EXPERIENCE

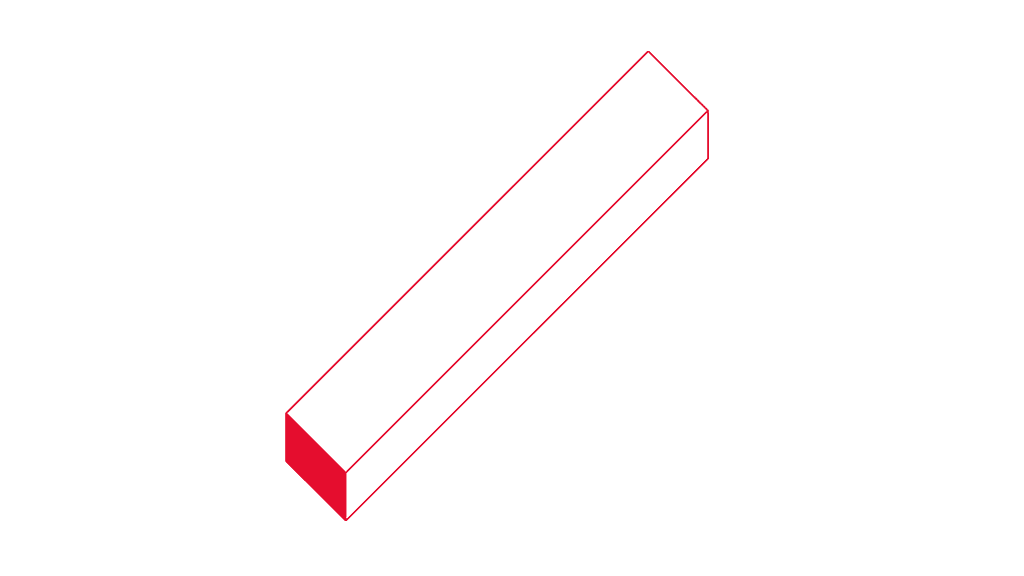

Our trusses are made of top-quality timber, strength graded by mechanical and visual methods and kiln-dried to an optimum moisture content of 18% (+/-2%). The four-sided planing process and bevelling of the edges make the timber less susceptible to pests and fungi and more fire retardant. In addition, depending on the intended use of the roof trusses, we provide various types of preservative treatment: with AXIL (against fungi, mould and insects) and FOBOS M4 (flame retardant treatment). For the production of truss elements, on the other hand, we use Mitek nailing plates, which are the most modern way of joining timber structures.

Production under proven conditions by experienced employees means that we are fully responsible for the strength and durability of the roof trusses, in line with the current standards, and guarantee that there are no deviations in the dimensions of timber.

WE KNOW A LOT ABOUT THE WOOD AND WOODWORKING

Prefabricated roof trusses - way to lower investment costs

- ease of processing

- strength and durability in accordance with PN-EN 14250:2011, PN-EN 1995 standards

- no deviation of dimensions of the timber

- possibility to eliminate supporting posts in attics

- possibility to slim down foundations and reduce the number of load-bearing walls inside the building

- elimination of heavy and expensive concrete floor

- production under proven conditions by skilled workers based on guidelines from our own design office

- fast and very precise assembly (the structure is delivered to the construction site complete with design, trusses and assembly fittings)

- biodegradable and low carbon footprint

- the possibility of preservative treatment against fungi, mold and insects, as well as flame retardant treatment

In addition to aspects such as fast completion of the investment, versatility of use, easy processing or attractive price, roof trusses are also a product that perfectly meets the expectations of environmentally-minded investors. Wood is a completely biodegradable material, while the production process itself leaves a much smaller carbon footprint than concrete.

Product comparison

| NAME | ||||||

| PRODUCT STANDARD | PN-EN 1995 | |||||

| TYPE OF WOOD | ||||||

| STRENGTH CLASS | ||||||

| MOISTURE | ||||||

| WOODWORKING | ||||||

| PRESERVATIVE TREATMENT (method of protection) | ||||||

| TYPES OF SURFACE QUALITY | ||||||

| BONDING (glue adhesive used for bonding) |