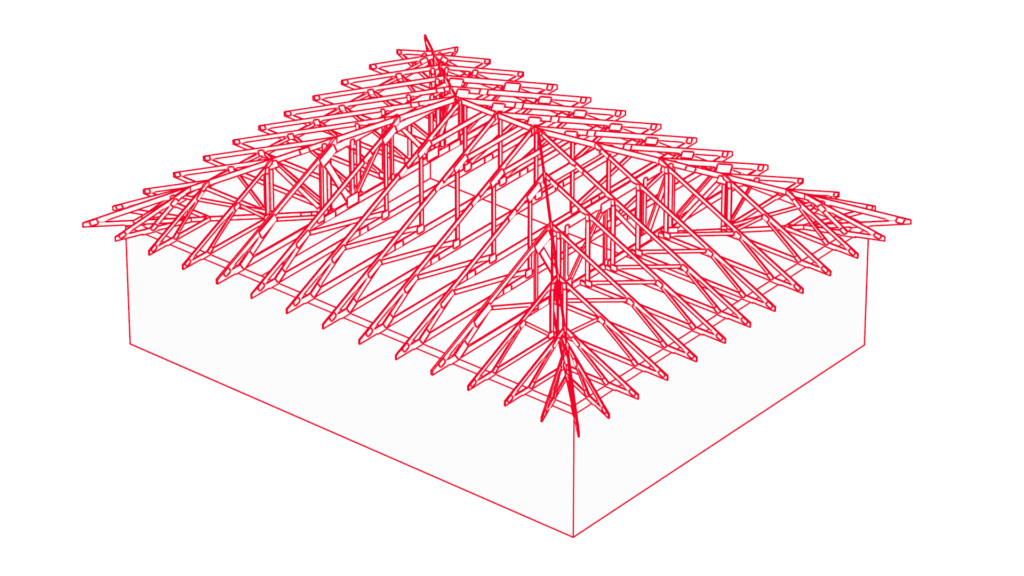

Prefabricated trussed rafters

The conventional prefabricated trussed rafters we offer meet the needs of different types of construction:

Single-family residential

Multi-family residential

Industrial

Agriculture

Public utility

Timber framed construction

“CUSTOM-MADE” DESIGN

Safe and cost-effective design

Top-class carpentry

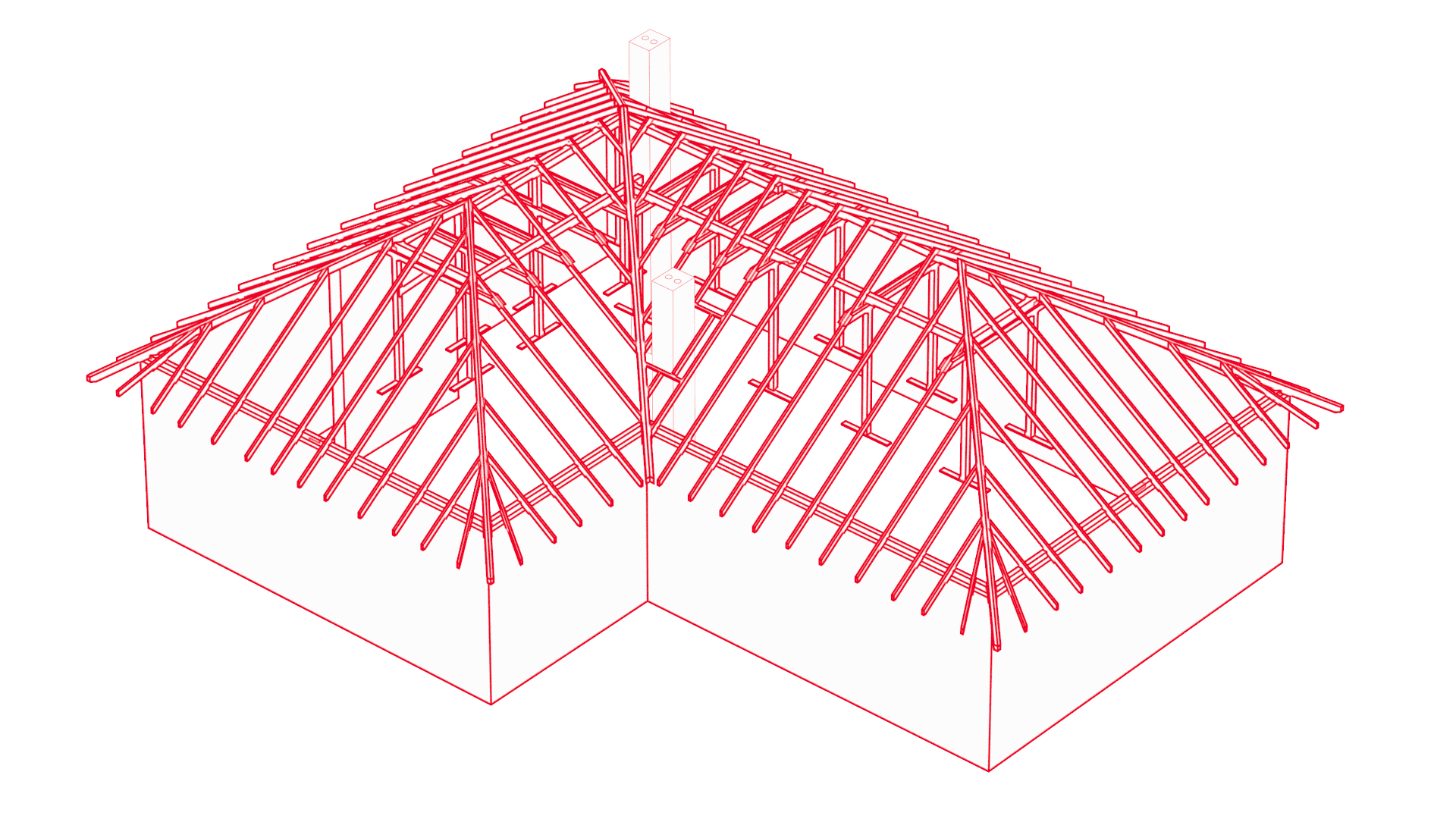

Prefabricated conventional trussed rafters combine all the advantages of carpenters’ craftsmanship with the advantages of prefabrication, i.e. precision and speed of timber processing.

Once all the elements of the trussed rafter have been cut to length, the corresponding carpentry joints are made and each element is numbered, which significantly optimises and facilitates the work and speeds up assembly on site.

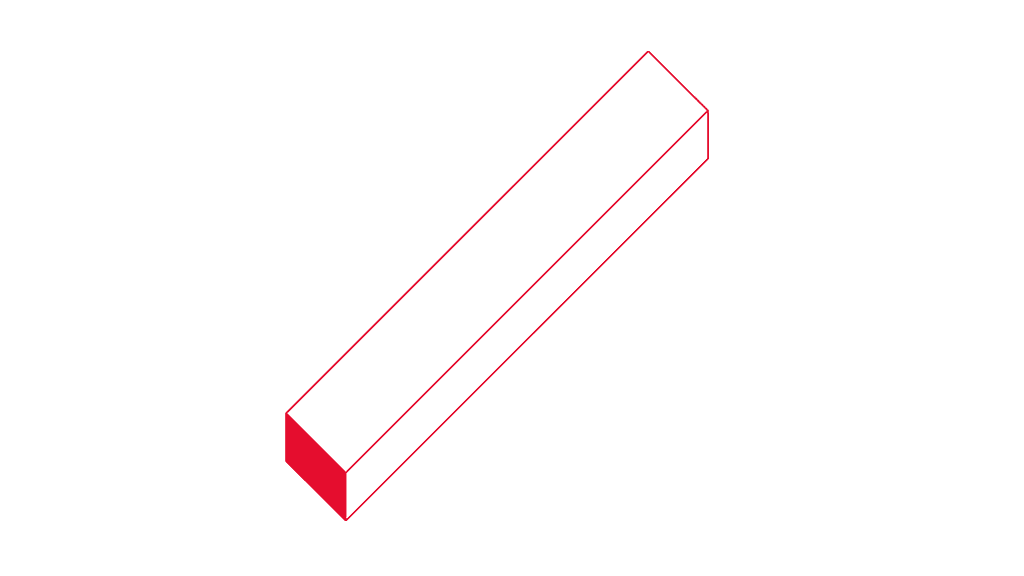

All prefabricated trussed rafter elements are cut to size with great precision, enabled by the high-tech Hundegger K2i joinery centre. The state-of-the-art machinery makes it possible to achieve a first-class product, and the precision, durability and strength of the woodworking joints in the prefabricated structures is incomparable to that which can be achieved on the construction site.

The produced trussed rafters are transported to the construction site as ready-to-assemble, numbered elements. This makes assembly considerably faster, optimising working time and saving money.

We know a lot about the wood and woodworking

Conventional prefabricated trussed rafter - saving money, time and labour

- optimal use of material

- precision of woodworking joints impossible to achieve on site

- diverse woodworking options

- can be impregnated against fungi, mould and insects

- clean, simple and quick assembly on site using the assembly diagram

- lower investment cost, reduced construction time

- design of prefabricated trussed rafter prepared by own design office

- excellent aesthetics and durability of structure

In addition to aspects such as short completion time, accuracy and precision of the prepared elements, conventional prefabricated trussed rafter is also a product that perfectly meets the expectations of environmentally minded investors. Wood is a completely biodegradable material, while the production process itself leaves a much smaller carbon footprint than concrete.

Product comparison

| NAME | ||||||

| PRODUCT STANDARD | PN-EN 1995 |

|||||

| TYPE OF WOOD | ||||||

| STRENGTH CLASS | ||||||

| MOISTURE | ||||||

| WOODWORKING | ||||||

| PRESERVATIVE TREATMENT (method of protection) | ||||||

| TYPES OF SURFACE QUALITY | ||||||

| BONDING (glue adhesive used for bonding) |